Top Tips for Improving Aquaculture Outcomes

/Though mostly known for its mining industry, particularly iron ore and natural gas, Australia also produces and exports a considerable amount of aquaculture products. Indeed, aquaculture is a vital and rapidly growing part of Australia’s globally important food production sector. From barramundi and Atlantic salmon to oysters, mussels, and prawns, farmed seafood now accounts for 42% of domestic seafood supply and a growing proportion of Australia’s high-value exports.

Several factors are now coming together to make aquaculture businesses and investors hopeful about the industry. For instance, there’s now significant global pressure to limit wild-caught seafood, coinciding with a rapidly expanding global middle class that’s eager to consume more high-quality food items. Continued innovation in sustainability and infrastructure is also helping aquaculture businesses address both practical and legal concerns while also maintaining profitability.

However, multiple challenges persist for Australian aquaculture operators. The country’s immense biosecurity risks, often-harsh environmental conditions, and the remoteness of many aquaculture operations can make it exceedingly difficult to safely and consistently turn a profit.

Aside from those challenges, regulatory compliance remains complex and varies across jurisdictions, requiring operators to stay informed and adaptable. Climate variability and extreme weather events, such as flooding or marine heatwaves, can also disrupt growth cycles and damage infrastructure. These obstacles make it critical for aquaculture businesses to adopt forward-thinking strategies that enhance resilience and optimize resource use.

Fortunately, even small improvements in infrastructure, site layout, or day-to-day practices scale well in aquaculture operations, helping operators enjoy better yields with relatively modest fixes. Here are some important tips that operators can use to improve aquaculture outcomes without completely overhauling their setups.

1. Use Reliable Pipe Floats to Stabilize Water Infrastructure

Floating pipelines are used in many aquaculture operations, often as main components of offshore cages or automated feeding systems. If these pipelines aren’t made to spec, they can sink, twist, or become damaged due to repeated wave action or strong currents—all common hazards in many of the marine aquaculture areas of Australia. When looking up pipe floats for sale, it makes sense to prioritize durable polyethylene floats to keep pipes buoyant and securely positioned, even amidst strong waves.

2. Choose UV-Stabilized Materials to Withstand Harsh Conditions

Aquaculture infrastructure is often exposed to intense sun year-round. While they may be functional at the start, equipment made from less-durable plastics can rapidly degrade from UV exposure, becoming brittle and prone to failure. Selecting floats and other fittings made from UV-stabilized polyethylene ensures that equipment continues to function as intended, avoiding work stoppages and costly replacements.

3. Invest Time in Site-Specific Design and Layout

Factors such as water depth, current flow, wave exposure, temperature, and salinity directly impact fish health and growth rates. This means that both the specific location and the supporting infrastructure must be accounted for in order to ensure more successful yields.

Fortunately, while there are often limits on the locations that can be used, aquaculture operators can almost certainly develop infrastructure to make the most use of the available space. With detailed site assessments, fish cages, moorings, and feeding systems can all be optimized to consistently enhance stock well-being without seriously impacting operations.

4. Automate Water Quality Monitoring

Oxygen levels, temperature, pH, salinity, turbidity, and ammonia concentrations can all affect stock growth rates and mortality. In traditional setups, water samples would have to be taken periodically and sent to a lab for analysis. This isn’t always ideal, given that water conditions can sometimes change in a matter of hours. Adopting automated sensors and cloud-based monitoring systems is a viable solution. It enables operators to track multiple key parameters in real time, enabling a quick response to environmental changes and reducing the risk of disease outbreaks or stress-related losses.

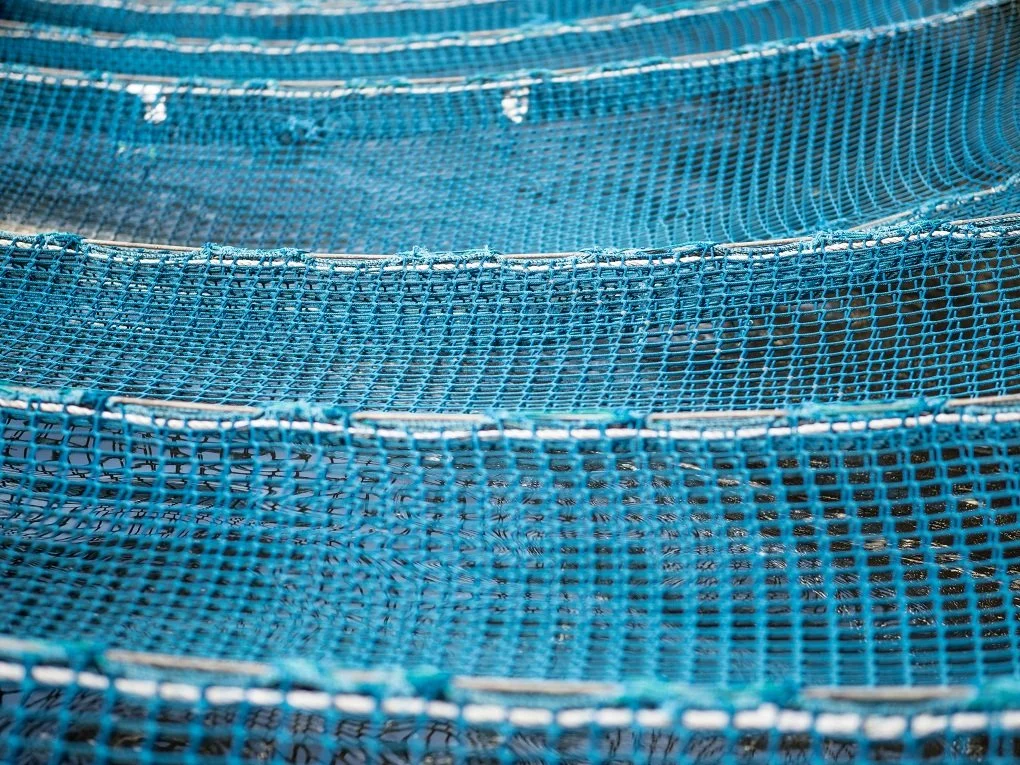

5. Invest in High-Quality Nets and Stock Enclosures

Low-grade nets may tear easily or become quickly fouled with algae and barnacles, impeding water flow and requiring frequent cleaning. Aside from being more durable, modern net styles can reduce both fouling and maintenance times, often making them worth any additional costs. They’re also better able to maintain proper tension, preventing escapes and entanglements.

6. Emphasize Preventive Maintenance Practices

Aquaculture sites are often located in challenging environments far from logistics hubs. As a result, it’s not uncommon for equipment to fall behind on maintenance, succumbing to corrosion, marine growth, and mechanical stresses over time. This is why a proactive approach to maintenance is key.

Operators must look into developing regular inspection and service schedules, not just for key equipment but also for the sensors used to monitor them. This should help avoid unexpected failures and enable the early identification of serious problems before they lead to negative business impacts.

7. Periodically Train and Upskill Your Team

The difference between aquaculture operations is often less about equipment or genetic selection than it is about staff quality. Regular training and refreshers help ensure that staff are better able to handle key biosecurity protocols, safety procedures, and equipment. More frequent training can also leave staff better equipped to respond to emergencies that can easily happen at remote aquaculture sites.

Small Changes for Smarter, More Profitable Aquaculture

Aquaculture is a long-term practice where even small improvements lead to tangible gains in efficiency, sustainability, and profitability. Though every site is different, applying just a few of these ideas can lead to lower risks and better outcomes over time. Be sure to see what works best for your unique environment and to carefully weigh your options before committing.

As the sector continues to grow, operators who prioritize smart investments in technology, proactive risk management, and workforce training will be better positioned to navigate evolving market and environmental conditions. Collaboration with researchers, government agencies, and supply chain partners can also unlock access to new tools, grants, and best practices. Long-term success in aquaculture increasingly depends on adopting a mindset of continuous improvement—where data, innovation, and practical know-how intersect to build resilient, productive systems. Whether you’re a small operator or managing a larger enterprise, focusing on gradual, evidence-based enhancements can lead to sustained profitability and environmental stewardship. In a competitive and dynamic global market, these incremental advantages often make all the difference.

About the Author:

Nicole Puller is a freelance writer and guest contributor who covers a wide range of topics, including sustainability, infrastructure, and emerging industry trends. She brings a practical, research-driven approach to her writing, helping readers navigate complex subjects with clarity and insight.

You may also be interested in…

Though mostly known for its mining industry, particularly iron ore and natural gas, Australia also produces and exports a considerable amount of aquaculture products. Indeed, aquaculture is a vital and rapidly growing part of Australia’s globally important food production sector. From barramundi and Atlantic salmon to oysters, mussels, and prawns, farmed seafood now accounts for 42% of domestic seafood supply and a growing proportion of Australia’s high-value exports.